-

Titanium buisleidingen

-

Titanium Gelaste Pijp

-

Titanium pijpflens

-

Naadloos Titaniumbuizenstelsel

-

TitaniumWarmtewisselaar

-

Het Buizenstelsel van de titaniumrol

-

Het Blad van de titaniumlegering

-

Titanium bevestigingsmiddelen

-

Titanium lasdraad

-

Titanium Ronde Bar

-

Titanium smeedstukken

-

Titanium Bekleed Koper

-

Titaniumelektrode

-

Metaal Sputterend Doel

-

Zirconiumproducten

-

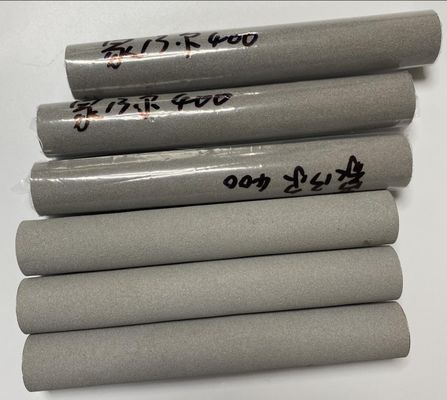

Gesinterde Poreuze Filter

-

De Draad van Nitinol van het vormgeheugen

-

Niobiumproducten

-

Wolframproducten

-

Molybdeenproducten

-

Tantaalproducten

-

Producten van apparatuur

-

aluminiumproducten

-

roestvrij staalproducten

Porous Sintered Metal Filter Tube SS 316L For Catalyst Recovery Chemical

| Plaats van herkomst | CHINA |

|---|---|

| Merknaam | CSTY |

| Certificering | ISO 9001;2015 |

| Modelnummer | SS 316L |

| Min. bestelaantal | 5-10pcs |

| Prijs | USD56/pc |

| Verpakking Details | film en houten koffer, karton Verpakking kan worden volgens de eisen van de klant. |

| Levertijd | 10-15 dagen |

| Betalingscondities | L/C, T/T, Western Union, MoneyGram, PayPal |

| Levering vermogen | 200 stcs/maand |

Contacteer me voor vrije steekproeven en coupons.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Als u om het even welke zorg hebt, verstrekken wij de online-Help van 24 uur.

x| Schuurweerstand | Hoog | Temperatuurweerstand | ≤400℃ |

|---|---|---|---|

| De steekproefdienst | Verstrek steekproef voor het testen | Maximale druk | 2.0Mpa |

| Materiaal | SS 316L, Titanium, Inconel600, Monel400, ETXC. | Andere service | Platium, IRL, Ru de plaat van het deklaagtitanium |

| Oppervlaktebehandeling | Polijsten | Filtratiegebied | 0.3-1.0m2 |

| Voordeel | hoge porositeit en doorlaatbaarheid | Type | titanium filterelement |

| Compressieve sterkte | ≥0,6 mpa | Filterbeoordeling | 0,5um-50um |

| Filtermedia | Nikkelpoeder | Werkend leven | Meer dan 10 jaar |

| Temperatuur | 0-200 ℃ | ||

| Markeren | gesinterde metalen filterbuis SS 316L,porieus metaalfilter voor catalysatorherstel,gesinterd poreus filter voor chemische stoffen |

||

Introduction

Compared with traditional filtration materials such as paper, cotton, PP, PE, PES, and PTFE, metal powder sintered porous materials offer superior performance.

They feature excellent permeability, uniform pore size and pore control, stable shape, high filtration accuracy, wear resistance, and outstanding mechanical strength.

Additionally, these materials exhibit good heat conduction, heat resistance, and dissipation performance, allowing them to be washed and reused multiple times without significant loss of performance.

Specifications

| Product Name | SS 316L Sintered Tube |

|---|---|

| Material | Pure Titanium / SS316L / Bronze |

| Size | OD 20–80 mm × WT 2.5–3.0 mm × L 10–1200 mm |

| Filter Accuracy | 0.5–80 µm |

| Connection | Customized according to customer requirements |

| Applications | Sparging, Separation and Filtration, Carbonation, Liquid Filtration, etc. |

Technical Parameters

| Filter Accuracy (µm) | Porosity (%) | Permeability (m³/m²·h·kPa) | Compression Strength (MPa) | Temperature Tolerance (°C) | Max Working Pressure (MPa) |

|---|---|---|---|---|---|

| 0.5–50 | 20–50 | 3–800 | 2–3 | 250 | 0.6 |

Performance Features

Excellent mechanical strength and structural stability

Uniform pore size distribution and good air permeability

Superior chemical stability and corrosion resistance

High temperature resistance (up to 250 °C)

Acid and alkali resistance

Fireproof, anti-static, and reusable

Long service life with consistent filtration efficiency

Application Environments

Suitable for use in environments containing:

Nitric acid, sulfuric acid, acetic acid, oxalic acid, phosphoric acid, 5% hydrochloric acid, molten sodium, liquid hydrogen, liquid nitrogen, hydrogen sulfide, acetylene, water vapor, hydrogen gas, coal gas, carbon dioxide gas, and other chemically aggressive media.

Widely used in:

Catalyst recovery and chemical processing

Beverage and food production

Metallurgy and refining

Coarse and fine liquid filtration

Dust and oil mist removal from gases and vapors

Sound attenuation, flame retardancy, and gas buffering applications